-

Login or registerAlready Registered?

*Mandatory Fields

Don’t have an account yet?Please create your account to access the benefits.

Register -

My Wishlist

0

My wishlistMy wishlist

-

Happy Sport watchesAll creationsDiscover more

Happy Sport watchesAll creationsDiscover more -

Alpine Eagle watchesAll creationsDiscover more

Alpine Eagle watchesAll creationsDiscover more -

Happy Diamonds watchesAll creationsDiscover more

Happy Diamonds watchesAll creationsDiscover more -

Mille Miglia watchesAll creationsDiscover more

Mille Miglia watchesAll creationsDiscover more -

L'Heure Du Diamant watchesAll creationsDiscover more

L'Heure Du Diamant watchesAll creationsDiscover more -

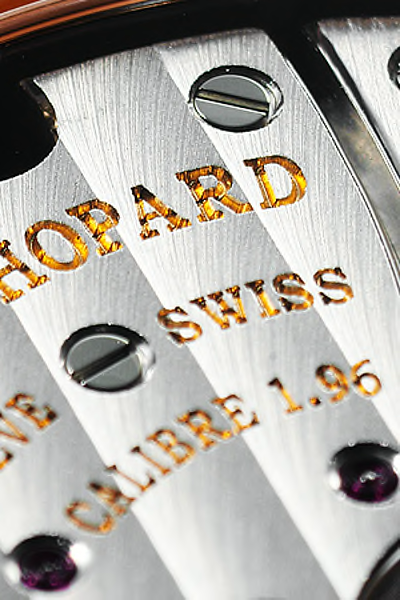

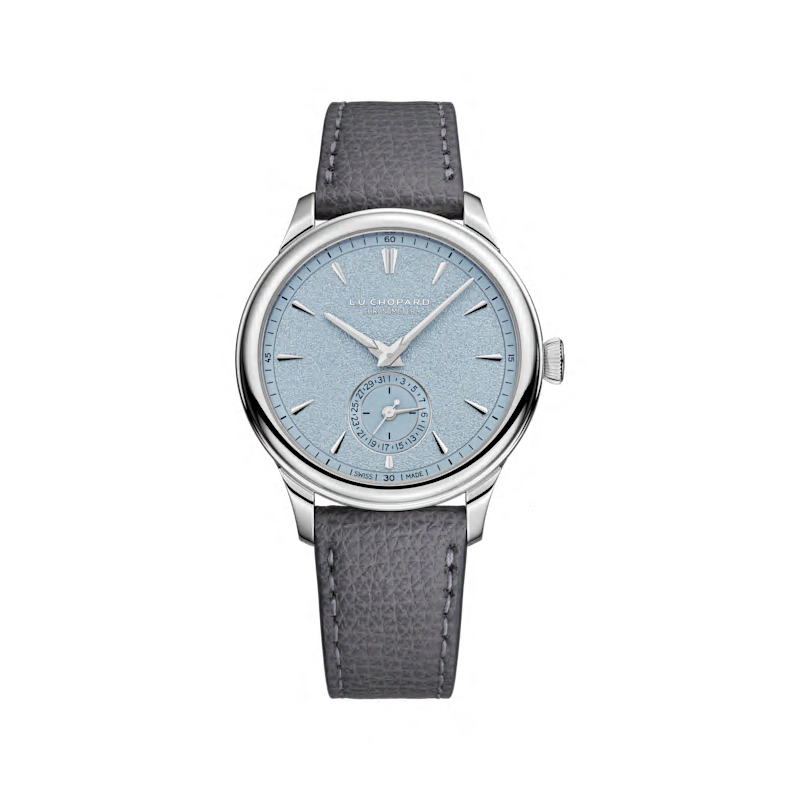

L.U.C watchesAll creationsDiscover more

L.U.C watchesAll creationsDiscover more -

IMPERIALE watches

IMPERIALE watches -

All Watch Collections

All Watch Collections

-

Happy Hearts necklaces & pendantsAll creationsDiscover more

Happy Hearts necklaces & pendantsAll creationsDiscover more -

Happy Diamonds necklaces & pendantsAll creationsDiscover more

Happy Diamonds necklaces & pendantsAll creationsDiscover more -

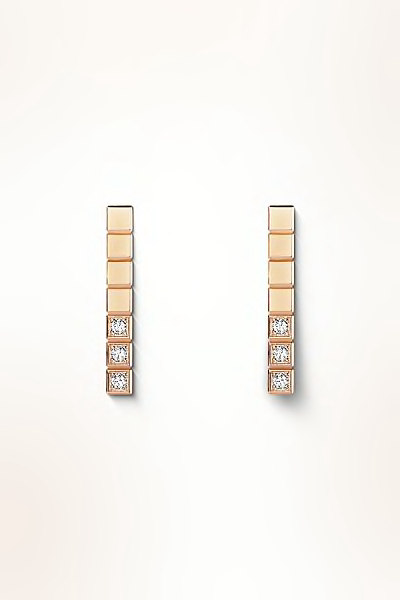

Ice Cube necklaces & pendantsAll creationsDiscover more

Ice Cube necklaces & pendantsAll creationsDiscover more -

Precious Lace necklaces & pendantsAll creationsDiscover more

Precious Lace necklaces & pendantsAll creationsDiscover more -

L'Heure Du Diamant necklaces & pendantsAll creationsDiscover more

L'Heure Du Diamant necklaces & pendantsAll creationsDiscover more -

All necklaces & pendants

All necklaces & pendants