As reflected in its Journey to Sustainable Luxury, Chopard is committed to responsible sourcing throughout its supply chains.

Recognising that risks of significant adverse impacts may be associated with the extracting, trading, handling, and exporting of minerals, in particular when sourcing from Conflict-Affected and High-Risk Areas (CAHRAs), Chopard sets a number of principles in its Responsible Sourcing Policy and continuously strengthens its management system for due diligence.

Responsible Sourcing Policy

The Responsible Sourcing Policy and Code of Conduct for Partners are available on Chopard’s Sustainability webpage in the section Responsible Sourcing Programme.

The due diligence system is applicable to all Chopard's suppliers of precious metals, minerals and gemstones (sapphires, rubies, emeralds, diamonds, semi-precious stones, etc.).

Internal Management

Chopard’s Head of Corporate Sustainability (HCS) leads the supply chain due diligence system and the audit programme. In doing so, the HCS works closely with Chopard’s purchasing team dealing directly with the suppliers.

The system is overseen by the company’s Chief Financial Officer (CFO), who is alerted by the HCS of any potential red flags that arise with regards to the company’s sourcing practices. The CFO reports to the board on these issues.

Control and Transparency System

Since the beginning of 2023, Chopard is conducting and recording its supply chain due diligence on a digital platform tailored-made to its management system.

Chopard maintains a Supply Chain Map of all its suppliers of precious metals, minerals and gemstones with information about the different tiers down to the origin of raw materials (when possible). To collect this information, Chopard engages with its suppliers through, among others, sustainability and traceability questionnaires, digital platform, publicly available information, interviews, and on-site visits. All documents accompanying the precious goods are also scanned and archived on its servers, guaranteeing computerized traceability between the supplier's documents (transfer documents) and its unique receipt numbers.

Gold: each supplier is required to detail on the delivery documents how the gold provided meets Chopard’s ethical gold requirements (transfer document) so that this information can be verified at each physical reception. Any discrepancy is directly reported to the precious material buyer and the material is segregated to avoid any mixing with the stock. The stock manager will wait for the buyer's instructions to release or return the material.

Diamonds: all diamonds purchased by Chopard are compliant with the Kimberley Process Certification Scheme (KPCS). Chopard requires its diamond suppliers to comply with the ‘System of Warranties’, a continuation of the KPCS that applies to polished diamonds. The compliance with this written warranty on its suppliers’ diamond’s invoices is regularly monitored. Chopard also requires all its diamonds’ suppliers to be RJC Code of Practices (COP) certified.

Coloured Gemstones: Chopard requires its coloured gemstones’ suppliers to provide relevant information (origin, treatments, etc.) on their invoices. Hence, Chopard requires its suppliers, with priority given to suppliers of sapphires, rubies, and emeralds, to register on the Gemstones and Jewellery Community Platform, to assess and report on their own supply chain due diligence practices. Since 2022, Chopard also requests its gemstone’s suppliers to become RJC COP certified within 2 years.

Happy Sport watchesAll creationsDiscover more

Happy Sport watchesAll creationsDiscover more Alpine Eagle watchesAll creationsDiscover more

Alpine Eagle watchesAll creationsDiscover more Happy Diamonds watchesAll creationsDiscover more

Happy Diamonds watchesAll creationsDiscover more Mille Miglia watchesAll creationsDiscover more

Mille Miglia watchesAll creationsDiscover more L'Heure du Diamant watchesAll creationsDiscover more

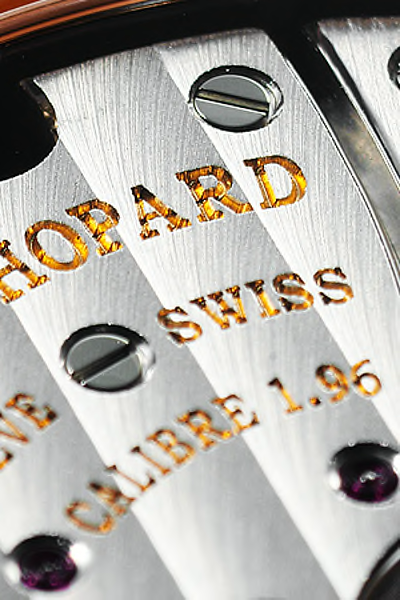

L'Heure du Diamant watchesAll creationsDiscover more L.U.C watchesAll creationsDiscover more

L.U.C watchesAll creationsDiscover more IMPERIALE watches

IMPERIALE watches All Watch Collections

All Watch Collections Happy Hearts necklaces & pendantsAll creationsDiscover more

Happy Hearts necklaces & pendantsAll creationsDiscover more Happy Diamonds necklaces & pendantsAll creationsDiscover more

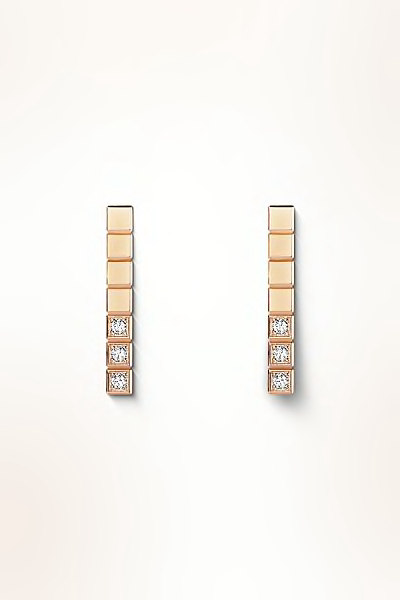

Happy Diamonds necklaces & pendantsAll creationsDiscover more Ice Cube necklaces & pendantsAll creationsDiscover more

Ice Cube necklaces & pendantsAll creationsDiscover more Precious Lace necklaces & pendantsAll creationsDiscover more

Precious Lace necklaces & pendantsAll creationsDiscover more L'Heure du Diamant necklaces & pendantsAll creationsDiscover more

L'Heure du Diamant necklaces & pendantsAll creationsDiscover more All necklaces & pendants

All necklaces & pendants