[Sustained note]

(On-screen text: Chopard presents)

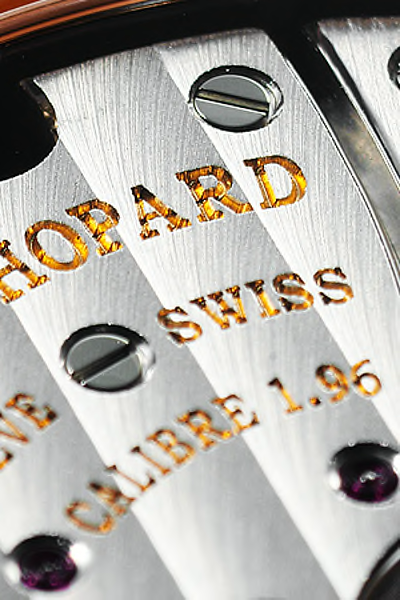

(Close-up of a watch movement, Mégane delicately puts a spring in place.)

My greatest memory at Chopard was the tour when I arrived. We went to see all the departments and professions, it was so interesting.

(Mégane sits down in her workshop, wearing a lab coat and eyepiece.)

What I really loved was the Chopard museum with all the pieces that have played a part in Chopard's history.

[Soft piano music plays]

(On-screen text: The word ART becomes ARTISAN.)

(On-screen text: From expertise to emotion. Chopard)

(A black and white graphite sketch of the palm of a hand, surrounded by the words EXPERTISE, CREATIVITY, EMOTION.)

So we always use both hands, one to keep the movement in place and the other to assemble.

(A portrait of Mégane.)

(On-screen text: Mégane, Apprentice Watchmaker)

One holds and the other works.

(On-screen text: Pinning up to the collet)

(Mégane uses tiny tools to work on a balance spring.)

But for the balance-spring, it's one tool in each hand, and you use both of them. When you start out, you're not ready to do that. You need to be ambidextrous, it's impossible.

(On-screen text: Bevelling)

As a child, I knew what I wanted to do, I wanted to be an art teacher or something similar. I wanted to do something with my hands, I looked into all kinds of trades, I saw watchmaking and I went for an introductory course at Chopard.

(A woman oversees Mégane working in the workshop.)

That is when I said: "That's what I want to do". There isn't a typical day, it always changes because we all do different things.

(On-screen text: Turning)

We start by working on the study timepiece first, on the micro-mechanics, and that is really our piece, our work, we spend many hours working on it. Polishing is a step I like a lot because it really enhances a piece, it takes a lot of time.

(On-screen text: Mirror-polishing)

You don't realize how long it takes, how far you can go to achieve perfection, which I love.

(On-screen text: Pivoting)

Pivoting, a technique that isn't used much any more, fascinates me, because you can do it all by hand, which is what I love. We then make the balance-spring, which is very complicated to make, it takes months to master it. Something else I love is at the end when you see the mechanism moving and working. You can very quickly upset something and it won't work any more. Actually yesterday it was the first time that I mounted a bridge that I made myself onto my piece. It was so beautiful, fully finished, I put it into place and saw that it worked, that's what is beautiful. You feel proud because it takes so long and the slightest thing can stop it from working, it's amazing to be able to say: "I made that".

(Mégane turns her balance-spring gently with a brush.)

Maybe one of the watches we've assembled and cased up will be worn somewhere across the world and it's us who finished the piece.

(On-screen text: Assembly)

(Close-up of a watch movement.)

It's amazing. I think this job suits me as I am a very shy person. I think this job is a good fit for me.

(Mégane puts parts in place on the movement.)

I love that the House of Chopard is like a big family. In every department, you can find former Chopard apprentices. It's a job I would like to do forever. It's the only thing I like.

(Mégane holds up the finished timepiece, studies it.)

(On-screen text: Chopard - The artisan of emotions - Since 1860)

Happy Sport watchesAll creationsDiscover more

Happy Sport watchesAll creationsDiscover more Alpine Eagle watchesAll creationsDiscover more

Alpine Eagle watchesAll creationsDiscover more Happy Diamonds watchesAll creationsDiscover more

Happy Diamonds watchesAll creationsDiscover more Mille Miglia watchesAll creationsDiscover more

Mille Miglia watchesAll creationsDiscover more L'Heure du Diamant watchesAll creationsDiscover more

L'Heure du Diamant watchesAll creationsDiscover more L.U.C watchesAll creationsDiscover more

L.U.C watchesAll creationsDiscover more IMPERIALE watches

IMPERIALE watches All Watch Collections

All Watch Collections Happy Hearts necklaces & pendantsAll creationsDiscover more

Happy Hearts necklaces & pendantsAll creationsDiscover more Happy Diamonds necklaces & pendantsAll creationsDiscover more

Happy Diamonds necklaces & pendantsAll creationsDiscover more Ice Cube necklaces & pendantsAll creationsDiscover more

Ice Cube necklaces & pendantsAll creationsDiscover more Precious Lace necklaces & pendantsAll creationsDiscover more

Precious Lace necklaces & pendantsAll creationsDiscover more L'Heure du Diamant necklaces & pendantsAll creationsDiscover more

L'Heure du Diamant necklaces & pendantsAll creationsDiscover more All necklaces & pendants

All necklaces & pendants